Compact Fluorescence Microscope XYZ Stage

Dover Motion collaborated with MyCartis to create a motion solution on a tight schedule, enabling the client to get the funding they needed to continue their project.

At a Glance

- MyCartis needed a motion control system to move and focus a microscope that would image thousands of 40-micrometer fluorescing microspheres arrayed on a plate.

- The motion system had to fit into the confined space of this benchtop instrument in a point of care setting.

- The positioning system needed to be developed in parallel with the instrument in order to hit a 12-month timeline.

How It Started

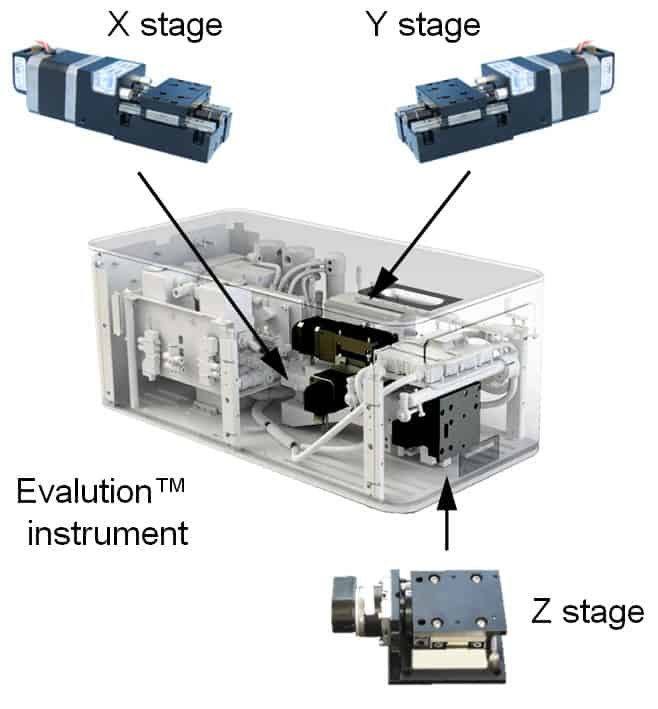

Belgian biotech startup company MyCartis was developing their next generation multiplex biomarker analysis platform that used fluorescent microscopy for molecular diagnostics. The instrument, Evalution™, was to perform a fast and highly sensitive detection of protein and nucleic-acid biomarkers using an epifluorescent microscope to scan a disposable, micro-fluidic assay plate.

To bring Evalution™ to life, MyCartis needed a multi-axis stage and motion control system that could precisely move and focus a microscope to image thousands of 40-micrometer fluorescing microspheres arrayed on the plate. MyCartis approached Invetech, a full-spectrum product realization company of which Dover Motion is a division, to develop the instrument and the Dover Motion team was tasked to create the motion system inside of it. Our track record with precision motion made us the perfect partner to build this system that would provide the positioning needed to deliver high-resolution, repeatable images.

Tight Schedules and Small Spaces

Not only did Evalution™ have to perform, it needed to physically fit upon a benchtop in a point of care environment in order to be truly effective. The use of compact stages was critical in minimizing the instrument’s footprint, which led to a secondary challenge: how to arrange the stages. With such a constrained space, the three stages the instrument needed couldn’t be arranged in a conventional stacking method and had to be tightly integrated within the instrument’s structure.

Adding to the challenge, MyCartis required an accelerated development schedule in order to secure funding, and the positioning system needed to be developed in parallel with the instrument within a 12-month timeframe.

How We Did It

In order to achieve MyCartis’s performance and timeline goals, Dover Motion worked closely with the engineers at Invetech to define the motion system requirements and tightly integrate the hardware into the overall instrument design.

Standard Dover Motion KV™-25 stages were used for the X and Y axes to position the microscope under the sample, saving both time and money. These compact stages incorporated stepper-motor-driven lead screws and rotary encoder position feedback. The KV™-25 stages delivered:

- More than 1 inch (25 millimeters) of travel

- A resolution of 0.6 micrometers

- 4 micrometers of flatness and straightness

- Around 3 micrometers of bi-directional repeatability

The Z stage used for focusing the microscope was designed using a stepper-motor-driven CAM drive and rotary encoder position feedback. It delivered more than 0.04 inches (1 millimeter) of travel and around 3 micrometers of bi-directional repeatability.

These three stages were strategically arranged around the microscope in a way that minimized their footprint. They were also positioned symmetrically cantilevered about their combined center of gravity to ensure the maximum stability of the optics. The camera was located at the center of gravity of the entire XYZ motion assembly so that the yaw, pitch, and roll errors were minimized.

The Final Product

Dover Motion designed and delivered a compact, integrated, and stable XYZ motion solution on schedule in a concurrent and collaborative engineering effort. The result was a compact fluorescence microscope XYZ stage. We worked closely with Invetech to integrate the three compact precision stages into the instrument’s structure. This minimized the instrument’s footprint and allowed it to be used on a benchtop in a clinical setting.

The project team ensured that the stages in the compact fluorescence microscope XYZ stage were balanced around the center of gravity of the motion and camera assembly. This minimized the effects of the yaw, pitch, and roll errors that can result from cantilevered loads and ensured stable images. And with stable system optics during imaging, the Evalution™ platform was capable of creating clear, high-resolution fluorescent microscopy images and enabled biomarker detection down to the femtogram/milliliter level.

Dover Motion’s delivery of an optimal motion control solution well within the tight schedule enabled MyCartis to obtain the desired funding to continue platform development.